Non Destructive Inspection

Eddy Current & Ultrasonic equipment

YOUR TRUSTED PARTNER IN NON-DESTRUCTIVE TESTING WORLDWIDE

CONTROLE MESURE SYSTEMES (CMS) is a leading manufacturer of Non-Destructive Testing (NDT) equipment, specializing in Eddy Current and Ultrasonic inspection technologies.

We design, engineer, and develop every component of our systems — mechanical, electrical, and software — entirely in-house. Our mission is to deliver high-quality turnkey solutions that enhance the safety, efficiency, and profitability of our customers’ operations.

Our multidisciplinary engineering team continuously researches, invests in, and develops innovative technologies to meet and exceed customer expectations. In addition, our in-house laboratory allows us to design and test a wide range of custom probes and coils, ensuring optimal performance for each application.

Founded in 1988, CMS is a private and independent company based in Burgundy, France.

To better serve our global clients, we expanded our presence with the opening of CMS Inc. in New York, USA, in December 2020.

We are proud to collaborate with some of the most prestigious manufacturers across the Aerospace, Nuclear, Metal, Automotive, and Rail industries, as well as many others. Our expertise, know-how, and continuous equipment innovation enable us to meet the increasingly complex and demanding requirements of our customers.

With an extensive global network of agents, we provide fast and reliable support wherever it is needed. CMS is present in Germany, Italy, Spain, Portugal, Switzerland, Austria, Czech Republic, Northern countries, Poland, Russia, Turkey, Egypt, Saudi Arabia, South Africa, China, South Korea, India, Thailand, Australia, Malaysia, Brazil, Mexico, the United States and more.

CMS at a glance :

-More than 3200 Eddy Current NDT equipment provided all over the world

-More than 30 immersion tanks in France for aerospace industry

-More than 1250 Ultrasonic instruments in France for aerospace and automotive industries

-More than 50 turnkey test benches combining Ultrasonic and Eddy Current testing delivered worldwide for the metallurgical industry (tubes, bars, wires, profiles, etc…)

-Commercial and technical representations in more than 19 countries

-More than 10 R&D projects, on a national and European scale

The most prestigious customers are trusting CMS to help them improve their quality worldwide.

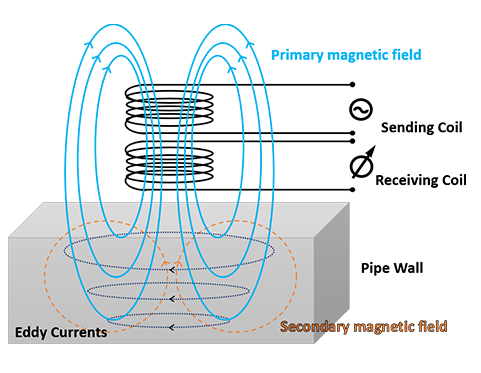

Illustration of Eddy Current inspection

In Eddy Current inspection, electrical currents are induced in a conductive material through a changing magnetic field. The resulting Eddy Current flow is measured, and any interruptions or alterations caused by material defects alert the operator to potential issues.

Eddy Currents are also influenced by a material’s electrical conductivity and magnetic permeability, making this method suitable not only for defect detection but also for material sorting and characterization applications.

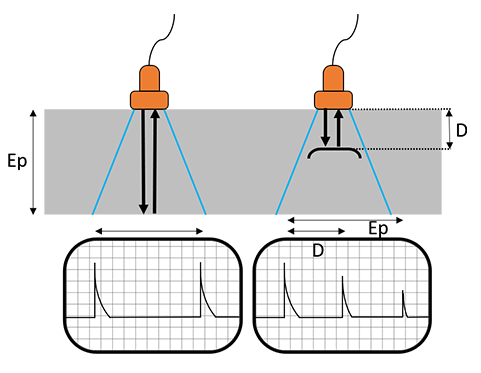

Illustration of Ultrasonic inspection

In Ultrasonic inspection, high-frequency sound waves are transmitted into a material to detect imperfections or identify changes in material properties. The most commonly used method is pulse-echo testing, in which a transducer emits sound waves into the material and receives the reflected echoes from internal flaws, changes in geometry, or variations in texture.

With a 30-year expertise in Eddy Current and Ultrasonic inspections, CONTROLE MESURE SYSTEMES provides high quality Non-destructive Testing solutions for industrial applications all over the world.

About us

Types of inspection

Service & support

Corporate Office

CONTROLE MESURE SYSTEMES

6 rue des Lochés

71100 Sevrey – FRANCE

+33 3 85 94 14 14

contactcms@cmsndt.com

CONTROLE MESURE SYSTEMES Inc.

67 West St. Suite 401

Brooklyn, NY 11222

+1 (347)684-9941

sales@cmsndt.com