Non Destructive Inspection

Eddy Current & Ultrasonic equipment

ULTRASONIC TESTING METHOD

Ultrasonic Testing method (UT) uses high frequency sound waves to conduct product examinations and make measurements. Ultrasonic testing inspection can be used for flaw detection, accurate dimensional measurements, material analysis and more. In high technology industries, the Ultrasonic method is increasingly used because it can perform Non-destructive Testing at different stages of the manufacturing process, as well as during usage of the product. Our UT equipment are adapted for a wide range of inspections.

Some examples of applications:

-

tubes and bars

-

aircraft wings

-

metal and composite structures

-

sheets

-

welds of tubes and pressurized containers

-

forgings of large dimensions (for power generation)

-

engine pistons

-

Wheelsets and rail axles

Our Ultrasonic testing systems are made of contactless instruments for automatic in-line inspection of tubes, pipes, bars or complex parts in Automotive, Aerospace, Metal and Nuclear industry. Our Ultrasonic rotating systems such as rotating head are dedicated to full body defect detection and dimensional measurements, our Ultrasonic local immersion tank for the inspection of tube and bar, and full immersion tanks for large parts.

Our goal is to develop and create performing solutions to improve safety, efficiency and profitability of our customers. We are constantly researching and improving the performances of our equipment and systems.

If you are looking for Ultrasonic solutions dedicated to ERW and SAW pipes inspection, discover SOFRATEST!

CMS provides Non-destructive Testing solutions for any defect detection

PRODUCTS :

PRODUCTS :

NDT solutions for Ultrasonic testing line of tubes and bars

NDT Eddy current (EC) and Ultrasonic (UT) rotating systems for defects detection on long products

MultiUTscan: for defect detection and dimensional measurement

MultiUTscan: for defect detection and dimensional measurement

MultiUTscan is a powerful and extremely accurate multi-channel & multi-frequency Ultrasonic inspection instrument.

It is dedicated for flaw detection and dimensional measurement of ID, OD, and wall thickness. The live inspection screens and user friendly interface make the ultrasonic configurations quick and easy to setup.

MultiUTscan is controlling all our UT equipment: the Ultrasonic rotating head RotoUTscan, the dimensional rotating head RotoUTdim, and the immersion tank.

Probus Supervision

Probus Supervision

Probus is a supervision software collecting information provided by various NDT equipment and process their data.

It is designed to be integrated as a quality control tool directly on the customer’s production line, to collect and display the signals of all the connected NDT instruments.

This supervision software is able to analyze the data, to communicate with the line to make a sorting decision, and to produce detailed inspection reports.

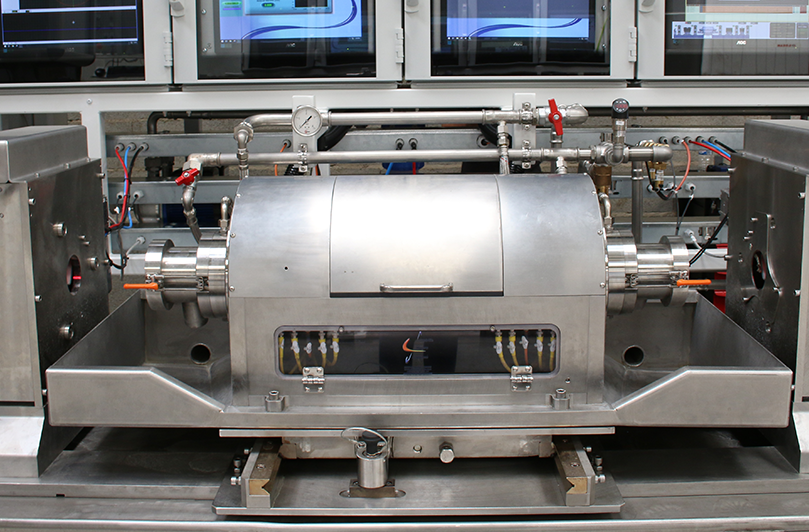

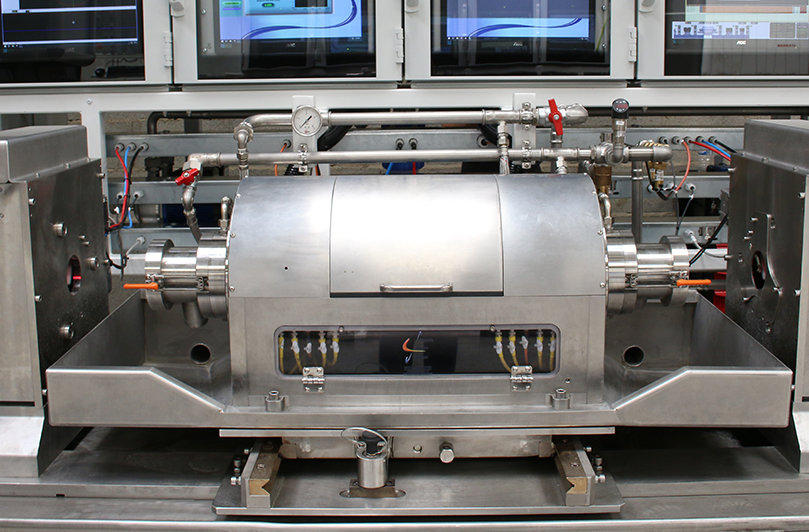

Ultrasonic rotating head RotoUTscan

Ultrasonic rotating head RotoUTscan

The inspected product is guided and moving through a water box (cassette), while the Ultrasonic transducers are rotating at a very high speed around it.

The transmission of the signals between rotor and stator is contactless. The collected signal is processed in real time and compared with the alarm thresholds previously defined in the supervision software.

The ultrasonic rotating head RotoUTscan allows the detection of internal and external defects of any orientation, and performs dimensional measurements (ID, OD, thickness, …) at a very high speed directly on the production line.

It is usually dedicated to the control of long products such as tubes, bars and wires made of stainless steel, carbon steel, titanium…

RotoUTscan can inspect diameters from 4 to 250mm.

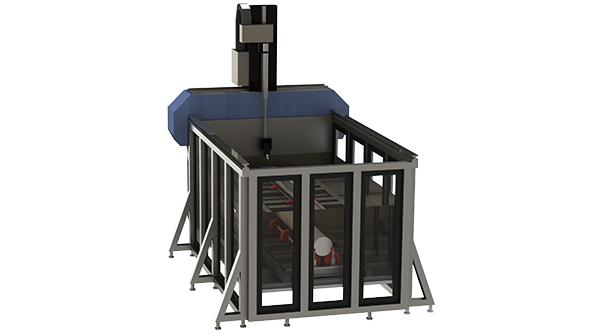

Ultrasonic Immersion Tank

Ultrasonic Immersion Tank

The part to be inspected is immersed inside the water tank. An industrial robot, programmable and capable of movements on up to six axes is holding the transducer, and moves it over the product to perform an highly accurate scanning process.

The Ultrasonic immersion tank provides scanning inspections carried out with conventional or phased array electronics, and can display the reports through A-scan, B-scan or C-scan.

A wide range of parts can be inspected using this technology (motor disks, bars, billets, plates, …).

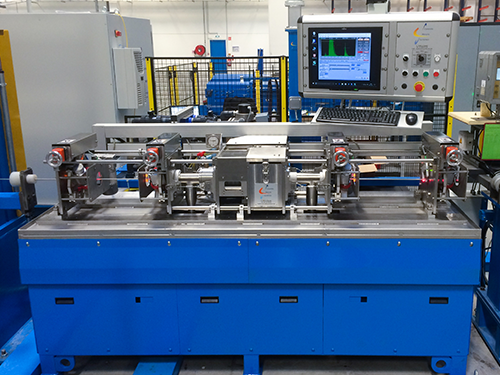

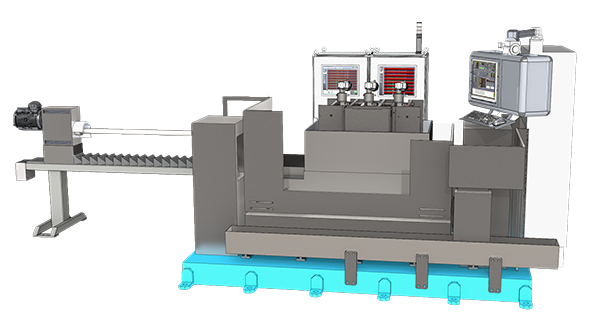

Bar and Billet Inspection

Bar and Billet Inspection

The Ultrasonic Phased Array Bar Inspection System allows a very high speed inspection of bars and billets.

Several sectorial Ultrasonic probes are installed on cassettes with an overlap at the entrance allowing a 360° inspection of the product. The arrangement of the sectorial probes and their type allow the detection of Flat Bottom Holes (FBH) or/and Side Drill Holes (SDH) also called longitudinal surface defects.

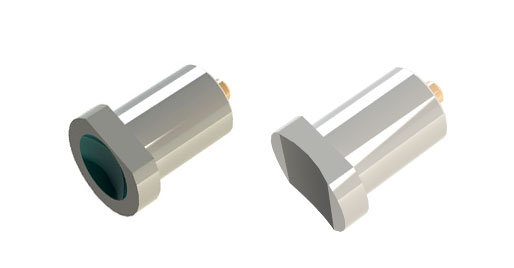

ULTRASONIC TRANSDUCERS

CMS provides Ultrasonic transducers such as :

- Rotating head transducers

- Spotweld transducers

- Contact transducers

- Specific transducers

ULTRASONIC ACCESSORIES

CMS provides a large range of accessories to combine with Ultrasonic instruments to conduct thorough and accurate product inspection:

- Centering devices

- Water circulation system

- Triaxial and RF cables

- Waterpath membranes

- Mechanical bench

- Coupling

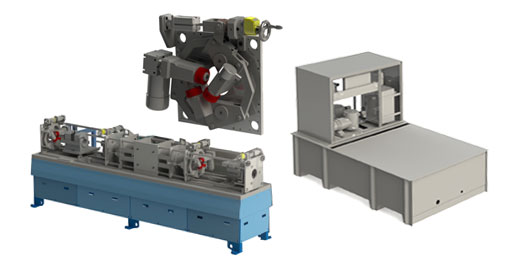

ENGINEERING AND TURNKEY SYSTEMS

Designing, planning, manufacturing, installing and setting up

With more than 30 years of experience, CMS gathered extensive knowledge in Ultrasonic testing. Our expertise in both mechanical and electrical design allow us to provide customized turnkey systems for the Medical, Automotive, Rail, Aerospace, Nuclear or Metal industries.

Some examples are: full body inspection of titanium tubes, quality control of bars, thick tubes in rotation, combined control bench using both ET and UT methods, and many more !

With a 30-year expertise in Eddy Current and Ultrasonic inspections, CONTROLE MESURE SYSTEMES provides high quality Non-Destructive Testing solutions for industrial applications all over the world.

About us

Types of inspection

Service & support

Corporate Office

CONTROLE MESURE SYSTEMES

6 rue des Lochés

71100 Sevrey – FRANCE

+33 3 85 94 14 14

contactcms@cmsndt.com

CONTROLE MESURE SYSTEMES Inc.

67 West St. Suite 401

Brooklyn, NY 11222

+1 (347)684-9941

sales@cmsndt.com